Processes

You are here : Products / Processes / TAD-1200

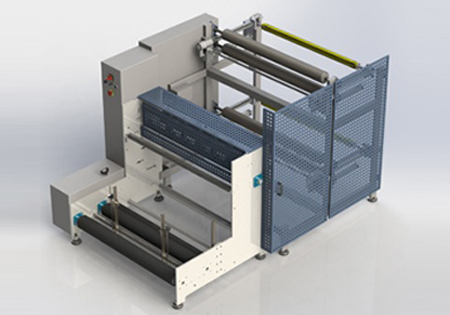

TAD-1200

DECOBINING AND CUTTERING MACHINE

The TAD-1200 cutter and winder is designed for cutting large sized gauze coils in smaller multiples sections for subsequent winding and thus obtaining smaller and more manageable rolls for machines without longitudinal cut, such as the SNM-3V.

It also allows the fabric to be optimally tensioned, improving the quality of the final rolls compared to other cutting methods such as guillotines.

Fully flexible machine to obtain different cuts according to customer needs, with little maintenance and giving a result of finished coils of great quality.

Possibility of several widths of machine, adapting to the client.

Designed and complying with the current machinery directives, (D89 / 392 / CEE, D73 / 23 / CEE and D89 / 336 / CEE), it has different alert systems to the operator in case the coil runs out and stops the machine.

It has a meter meter system to control the meters delivered in each coil and once the pre-established limit has been reached, stop the machine.

It has pneumatic rollers that adapt to the inner core of the coils, keeping them fixed.

TECHNICAL CHARACTERISTICS

| • Machine useful width: 1200mm. | • Transverse cutting system (Circular blades). |

| • Coil width 1200 (max diameter 900mm). | • Estimated production: 55m / minute. |

| • Number of ways: 6 ways. | • Counter with display and push buttons. |

| • Formats: 6 coils cut to 200mm (3 coils per way). | • Power: 380Vac. |

| • Expansible axes. | • Power: 1 motor of 1,5cv and a reducer of 7/1. |

| • Safety and protection system under CE regulations | • Air consumption: 4bar. |

*THE MACHINE WILL BE ADJUSTED ACCORDING TO THE MATERIAL PROVIDED BY THE CLIENT*.